“With metal and polymer manufacturing capabilities, Objectify has made its mark in providing efficient

additive manufacturing services to industries across the globe. From white goods to aerospace

components, we have been working relentlessly in improving our process and deployment strategies”,

said Mr. Ankit Sahu (Director, Objectify Technologies Pvt. Ltd.)

Whenever any industrial challenge arises, there is likely a capability and a team of people available to

overcome it. The following industrial solution case study fits the same bill. The only problem with the

industrial challenges is missed opportunities of not connecting the right team with adequate capabilities.

Objectify Technologies Pvt Ltd (OTPL) located in Delhi NCR is a leading name in additive manufacturing

solutions. OTPL believes in investing in state-of-the-art capital of well-trained engineering staff, the latest

Powder Bed Fusion type Selective Laser Melting machines (by EOS – M280, M290s including M400-4)

and allied post-processing 3-axis and 5-axis CNC milling centers to cater to Indian and overseas clients

need to produce quality parts with improved productivity for the least possible lead times.

“With the onset of new and improved additive manufacturing adaptation, India has come a long way in

idealizing the prospects of 3D printing for their manufacturing processes. This case study highlights

when an industrial challenge is tackled well, the new frontier of solutions evolves that helps build

competitive advantage for the industry,” said Mr. Rahul Pise (GM – Design & Operations, Objectify).

Challenge faced by the industry: An industrial player – our client (dealing with fluid flow machinery and

its control solution provider for oil and gas, energy and power, process industry) has a need for custom

design and custom-built centrifugal pumps. These types of design and make are low volume, high mix

type due to a variety of reasons. [Figure 1 – A schematic of centrifugal pump] The fluid flow rates,

pressure head essential to move the bulk fluid to elevation or to a distance, the fluid media

corrosiveness dictates geometry of setup, the choice of metal alloys to be used, the manufacturing

techniques for construction of rotating machinery of fluid pumps. Since these types of custom build

solutions are not the usual kind – high volume production units of saying water irrigation pumps with better

streamlined low-cost casting techniques for the centrifugal pump housing and its main rotating

component – the pump impeller.

For a particular customer of our client, a pump designed with an impeller to be made with non-corrosive

stainless steel grade SS316L but it was with the geometry that is closed impeller type and a dia of

300+mm. [Figure 2 – Geometric section of the closed impeller as an illustration] For such a unique impeller

shapes the development cost and lead time with conventional means of investment casting is quite

laborious efforts (almost to the extent as manual craftsmanship right from pattern making for lost-wax

approach) with several quality risks – such as unknown shrinkage of geometric features, unpredictable

porosity voids due to hot spots, rough surface finish of internal undercut features which are difficult to

process for manual grinding/polishing etc.

“We had to develop new parameters for SS316L to facilitate the build process. Various iterations of

support structures needed to be simulated for optimum results without failures. Also, since

undercutting the part wasn’t an option in conventional manufacturing via CNC milling, this gave a good

lead for us to proceed with EOS – M400-4 and we could make 100 parts per batch which even most

foundries don’t offer unless appropriate tooling for wax patterns and serious investment casting mold

making facility investments” said Mr. Arpit Sahu (Director, Co-founder – Objectify).

R&D Team of our client had been investigating, adoption of additive manufacturing for such low volume,

high mix need of 3D printing, complex closed impeller geometries under their new flagship of “Digital

Products and Solutions.” With a vision of making digital designs produced with digital data with the least

human interventions that allow competitive advantages. Competitive advantages are virtual storage of

design and production life-cycle know-hows for later duplications with near-perfect repeatability and

quality reliability, distributed manufacturing for supply and sourcing of products and replenishment

parts made to order, just in time with localized production facilities which are not requiring hefty

investments like in big foundries for tooling and facilities for casting.

Our client needed a 3D printing solution for an impeller of size 300+ mm which is not able to fit on the

usual-build-envelope of 3D printers that are of size 250mm x 250mm x 300mm. EOS, a German

manufacturer of powder bed fusion type 3D printers under flagship products – DMLS – Direct Metal

Laser Solidification had recently built a system that has a-build-envelope of 400mm x 400mm x 400mm,

could accommodate impeller of the size. However, with default EOS recommended processing

parameters to solidify the powder layer upon layer with the part orientation, the time taken was quite

long with quality risks involved. Risks such as layer shifting that affects geometric integrity, machine

stop and start stress lines/insufficient bonding if subsequent layers melting takes a too long time in case of

re-coater jamming issues etc.

Technical challenges in 3D-Printing closed impellers –

The geometry is a closed hollow shell, a classical problem that can only be tackled by 3D printing

as even 5-axis machining can’t cut curved vanes.

3D printing can allow us to accommodate hollow shells but still, the geometry needs to be

supported for a variety of reasons as the process dictates.

For quality and obvious difficulty in processing of internal features, them having support

structures is simply not a choice available.

Part orientation and support strategies to be optimized for successful 3D printing without

geometric integrity or strength quality issues.

Overcoming the obstacle:

The baseline – objectify is already equipped with an M400-4 machine which can accommodate 300+mm

dia closed impeller, isn’t the need already served? Is it that simple to load the digital design data on the

available machine and be done with it?

Although the media paints a rosy picture about 3D printing that the impressive geometry simply grows

at a click of a button, there is a team of several engineers and research & development know-how of

and not to neglect – several build crashes to master the craft with optimal process parameters of layer

thickness and Laser power exposure speed, geometric orientation, and support structure strategies.

Once these things are locked, getting successful prints as duplicates is quite reliable.

How the optimization is done?

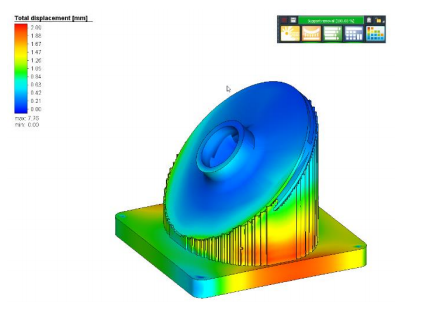

Thermal simulation of process based on voxel-based approach via Simufact (MSC’s AM FEA package)

the software gives an idea about thermal deformations induced due to thermal stress. Probable problem areas

can be identified (Figure 3 -Thermal induced stress causing displacement) and improved iteratively with

combination of change in part orientation, type and choice of support structures location, and amount of

support structure volume.

When process planning is robust, application – execution is precise as a rosy painted picture.

See Figure 4 for successful print completion.

Post-processing and finishing the part for delivery– See Figure 5.

Compared to 6 weeks to 8 weeks long effort in case of investment casting and finishing, 3D printing

took 1.5 weeks of printing and 2.5 weeks overall to produce this case study part as an alternative to

casting. Post-processing was comprised of –

Stress relieving heat treatment to ward off an-isotropic properties.

Support structure removal

Outside skin machining to remove support structure marks

Shot blasting

What lies ahead –

Our client has realized the potential of digital solutions for similar geometric complexity or other

complexities to be tackled. Non-corrosive type alloys like Titanium used for pumping specific chemical

media, 3D printed rapidly and timely with Objectify to meet their customer needs.

“Additive Manufacturing will pave the path for a better, sustainable future for mankind. The parts that

were built in this case took us only 6 days from ideation to post-processing, which would take 10 days or

more for conventional manufacturing processes with several byproduct wastes (wax, broken molds, etc.)

and energy consumed. It goes without saying that we have learned a lot from this project as we had to

test our capabilities to the utmost gravitas. With 100+ hours of non-stop machining time without

failures and offering 99.9% density of the material, Additive Manufacturing delivers the future in the

present.” concluded Mr. Ankit Sahu.

“Good Teamwork & Workmanship. Able to meet the delivery as promised.” in customer feedbacks, said

our client.

Objectify team is proud and happy when customer satisfaction is achieved through focused and

deliberate efforts to elevate the additive manufacturing standards and their applications.